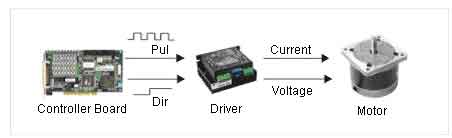

The stepper driver is one of the key

components in stepper system. As the diagram below,

based on the pulse / direction instruction (thin

current) from controller, the driver controls the

motor coil current (strong current), thereby to control

the rotation axis 's position and velocity. All of

the drivers in China Stepper Motor Inc. utilize the advanced bi-polar

constant current chopping mode to drive the stepper

motor.

Stepper Driver 's

Working Mode

There are three basic driving modes

for stepper motor: full step, half step & micro

step. They are differing in current control precision

in motor winding (i.e. excitation mode)

- Full Step Driving

During full step operation, both full/half stepper

and microstepping driver can be used for the

same stepper motor, but with different effect.

Based on the pulse/direction instruction, the

stepper driver excitated the two-phase stepper

motor 's two coils circularly (i.e. charging

the coils to set current), with this driving

mode, each pulse will make the motor run a

basic step angle, i.e. 1.8o (the standard 2

phase motor runs at 200 step angle per revolution).

- Half Step Driving

In uniphase excitation, the rotate shaft stop

in the full step position, when the driver

receive next pulse, the rotate axis will run

half step and stop in the middle of two full

step position on condition that excitated another

phase and keep it in excitation status one

by one. Keeping excitating the two-phase winding

with uniphase and biphase repeatedly, the stepper

motor will rotate at 0.90o per pulse in half

step mode. All of the China Stepper Motor Inc.TM full and half

step drivers can drive the motors with full

and half step mode, which is selected by one

of the driver 's switch-able switch. Compared

with full step, half step is superiority with

doubled precision and lower vibration during

low operation, herein between full and half

step mode, half step mode is usually preferable

in actual operation.

- Microstepping Driving

The microstepping drive has the advantage

of least vibration when running

at low speed & higher precision

when positioning. When the low

speed is needed (i.e. the rotate

shaft work at speed less than 60

rpm), or the position precision

is required to be less than 0.90

in stepping application, the microstepping

driver is used widely. The basic

principle is to control the motor

's two coils with precision current

by sine and cosine step separately,

thereby make one step angle divided

by several micro stepping. As the

diagram above, for instance 16

resolution step mode can make the

stepper motor with standard 200

step/rev. to achieve the running

precision at 200*16=3200 step/rev.

(i.e. 0.1125”). China Stepper Motor Inc.

can supply more than ten kinds

of microstepping drivers with complete

specification, superior performance,

reliable quality and competitive

price.

China Stepper Motor Inc.'s Advanced

Technology in Microstepping Drive

As one of the leading manufacturer

of stepper motors and drivers in China, China Stepper Motor Inc.

volume-produce the two-phase stepper driver with

high ratio of performance-to-price, which is suitable

for any 4, 6, and 8 leads homemade or imported

motor. Some of the drivers utilize the patented

technology from U.S. and the performance is highly

predominant. While most of the drivers is developed

by the Doctor & experts

in internal China Stepper Motor Inc. which have gained Chinese

patent and the ratio of performance-to-price is

much more attracted.

Selection Principle

- Driver 's current:

current is used to estimate

the driver 's capacity

and it is one of the most

important parameter to

select driver. Usually

the driver 's max. current

must be a little bit bigger

than the nominal current,

generally they are vary

from 2.0A, 3.5A, 6.0A,

8.0A and so on.

- Driver 's power

supply voltage:

the power supply voltage

is the criteria to estimate

the driver 's capability

of speed ascending. In general,

the supply voltage vary from

24VDC, 40VDC, 80VDC, 110VAC

and etc.

- Driver 's resolution:

Resolution is the key factor

to control precision, by

increasing resolution,

the precision can be improved.

Furthermore, higher resolution

can make the motor runs

more stably. Usually the

stepper motor vibrate at

low frequency, however

the vibration can be minimized

by increasing the resolution,

thereby make the motor

running smoothly.

Control Signal Interface Instruction

- Difference Interface:

Most China Stepper Motor Inc. drivers use

difference interface circuit,

set with photocoupler internally,

long winding drivers receiving

allowable, collector open

loop & PNP output circuit

signal, it is suitable

for any controller interface,

including Simens PLC. It

is recommended to use long

winding driver (e.g. AM26LS31)

circuit, which is advantaged

by anti interfere.

- Single / Double

Pulse Mode:

Most China Stepper Motor Inc. drivers can

receive two kinds of pulse

signal: one is pulse + direction

(single pulse); another is

positive pulse + negative

pulse (double pulse) mode,

it is selectable by the jump

machine in the driver.

|

|

|

|